In the previous years, most power plants were always in operation – referred today as baseload plants. They are like the central electrical home services that are constantly on. On the other hand, a peaking plant only runs when necessary, typically at peak times of the day or months of the year.

Because of plant operation at constant temperatures and pressures, the potentially detrimental effects and pressure changes are not an issue. Yet, temperatures may fluctuate daily by 500°F. The varying seasonal temperature is severe on the equipment, such as valves that can last to 30 years or more.

Traditional and modern valve types are used to meet the isolation valve requirements in these plants. Y-pattern globes and gate valves are typically used, not to mention the metal-seated butterfly valves and ball valves, for specific applications.

Gate Valves

Gate valves are still prominent in high-pressure steam service. Especially whenever there is a low-pressure drop through the open valve, the pressure drop is almost equivalent to a straight pipe. However, gate valves have drawbacks. An example is a higher leakage rate than globe valves and chances to trap fluid in bonnets. Different gate valve wedge models are used in high-pressure steam services. These are:

- split wedge – this design allows line loads and temperature transients quickly through each aligned wedge piece with its matching seat. This feature is used in large gate valves to beat thermal problems.

- flexible wedge – this design has several similar characteristics to split wedge designs. Their flexibility lets the wedge expansion and contraction besides the prevention of temperature locking into the valve body.

- parallel-expanding wedge – has intricate designs yet offers many advantages over other wedge type designs. Since the seat’s design has the potential to cause bi-directional sealing, internal body cavity fluid pressure can be locked in the valve.

- parallel expanding double-disc – Or parallel slide double-disc is constructed in two pieces with each piece floating independently and pair-off to its requisite body seat. This design yields much better immunity from thermal locking.

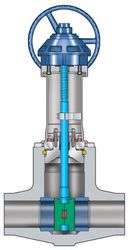

A pressure seal parallel slide gate valve.

Size of Gate Valve Port

When it comes to a below critical threshold in power plant applications, valves are sized at B16.34. These are generally designated dimensions, not regarding flow velocity and pressure drop. By the pressure of over 3,500 psi, fluid velocity and pressure drop relevant through the valve can be hazardous.

Moreover, noise is a side effect of high velocity, the reason why plants are not supposed to be near the general public area. For example, in the European Union (EU), they have strict requirements that are listed in the EU Environmental Health and Safety Guidelines. The guidelines state that no more than 55 weighted decibels during the day and 40 decibels at night. These are measured 500-meter from the source.

Globe Valves

A Y-pattern pressure seal globe valve.

Even if globe valves are known to throttle, they are used widely in valve applications for power plants. They have fewer operational issues compared to gate valves and provide excellent leak tightness. Because of their structure, globe valves need larger actuators. Although the Y-pattern globe valve has a better flow rate than the general T-pattern globe, it is still inferior to a gate valve when it comes to pressure drop, cavitation prevention, and velocity.

Ball Valves

Ball valves in power plant isolation facilities are bounded to metal-seated designs, same with high-performance metal-seated butterfly valves. Since these are non-trunnion kinds, the full force of the flow is directed onto the ball in the closed position. This signifies that these valves are restricted to smaller sizes and often decreased ports to diminish the necessary closure of torque.

The reduced port design makes a change in the capacity of the valve due to pressure loss and higher exit velocity. This is not a problem for drains and vents that are rarely operated. However, service issues could arise for continuous process applications.

Material Selection

The selection of materials for elevated temperature and high-performance valves is essential. The construction components must meet the required demands of relentless high-temperature usage while under stress from high internal pressures. Many mechanical properties are brought into play when choosing a metal. Their features must include tensile and yield strength besides ductility.

Creep Resistance

Given that these are all important, another attribute is fundamental when it comes to these conditions, and this is the creep resistance. To better understand what creep is, look at the yield strength property in steels. If a load that is less than the elastic restraint is applied at room temperature, the steel then elongates. And if the load is removed, then it will go back to its original shape or length.

The elastic feature will continue, notwithstanding the number of loadings created on the material. However, if an identical piece of steel is heated to increased temperature and a load is applied, the specimen may adopt a permanent deformation after some time. This may occur, although the applied load is under the elastic perimeter at room temperature. This phenomenon is what you call creep, and it can yield disastrous failures of metallic materials.

Conclusion

In summary, there is an extensive range of valves that can be used to withstand high-pressure and high-temperature conditions. Gate, globe, ball, and butterfly valves are the standard valves that can be applied to power plant applications. Each type has its advantage and disadvantage. To be rightfully guided on which isolation valve to use, it would be best to consult a reliable valve manufacturer.